Ceramics

India is a Large Hub of Natural Existing and Factory Processed Stones; with various processing pockets and a wide spread application of an array of Belts.

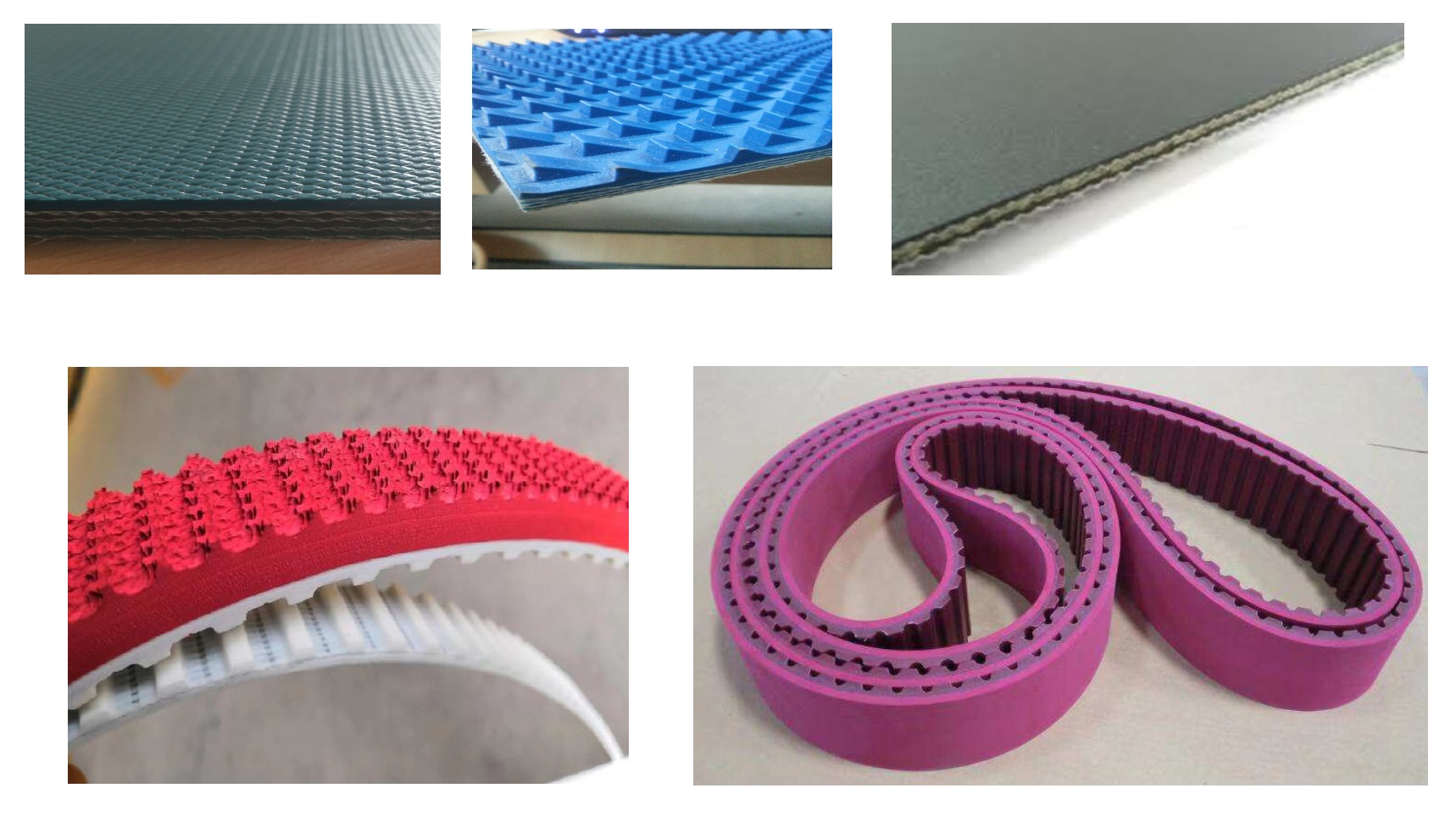

- Plied Conveyor Belts

The Plied Conveyor Belts are a manufactured with the consideration of High Load Conveying Capacity at larger lengths and a long durability for a 24x7 operation.

-

- Patterns on the Top Layer – This enables to hold the tiles at its position for an appropriate loading / transfer.

- Abrasion Resistance – Ceramics are highly abrasive due to the basic Raw Materials it contains. Belt needs to be durable

- High Tensile Strength – The Tensile Members used in the belts are the spine to Long Length along with the Carrying Capacity.

- Resistant to Chemicals & Inks – Printing operation involuntarily spills inks. The belt has to resist harsh nature.

- Timing Belts with Elastomer / APL Coating – Plain / Patterned

- Both the Covers play its formidable role for the Ceramic Sector. The high co-efficient of friction lets the Tiles / Stones be perfectly positioned for feeding for the processing and the timing belt ensures the periodic movement.

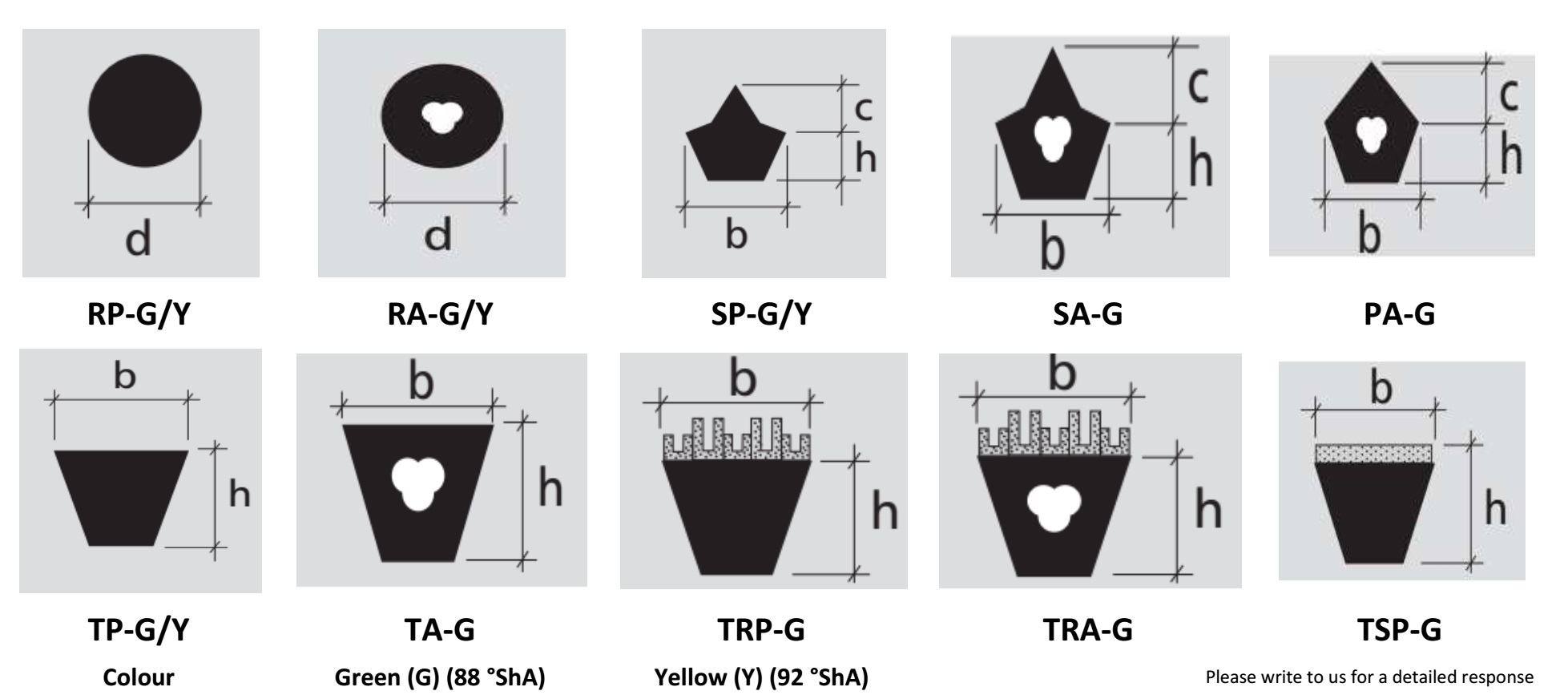

- Profiled Thermoweldable Belts

- The Profiled Belts provides Minimal Carrying Contact and Maximum Air Contact with the Hot & Soft Tiles with Minimal Marking and Maximum Cooling.

- The Cord Reinforcement adds to the additional strength required for a higher load carrying or Longer Length Carrying