Special Belts

Unique Belts can include a variety of options

- Belts for Sidewall and Cleats

- Belts with Foam on the Top

- Belts with Rubber Cups for unique conveying

- Curve Conveyor Belts

- Belts with Finger Cleats / Stud Cleats

Special Belts

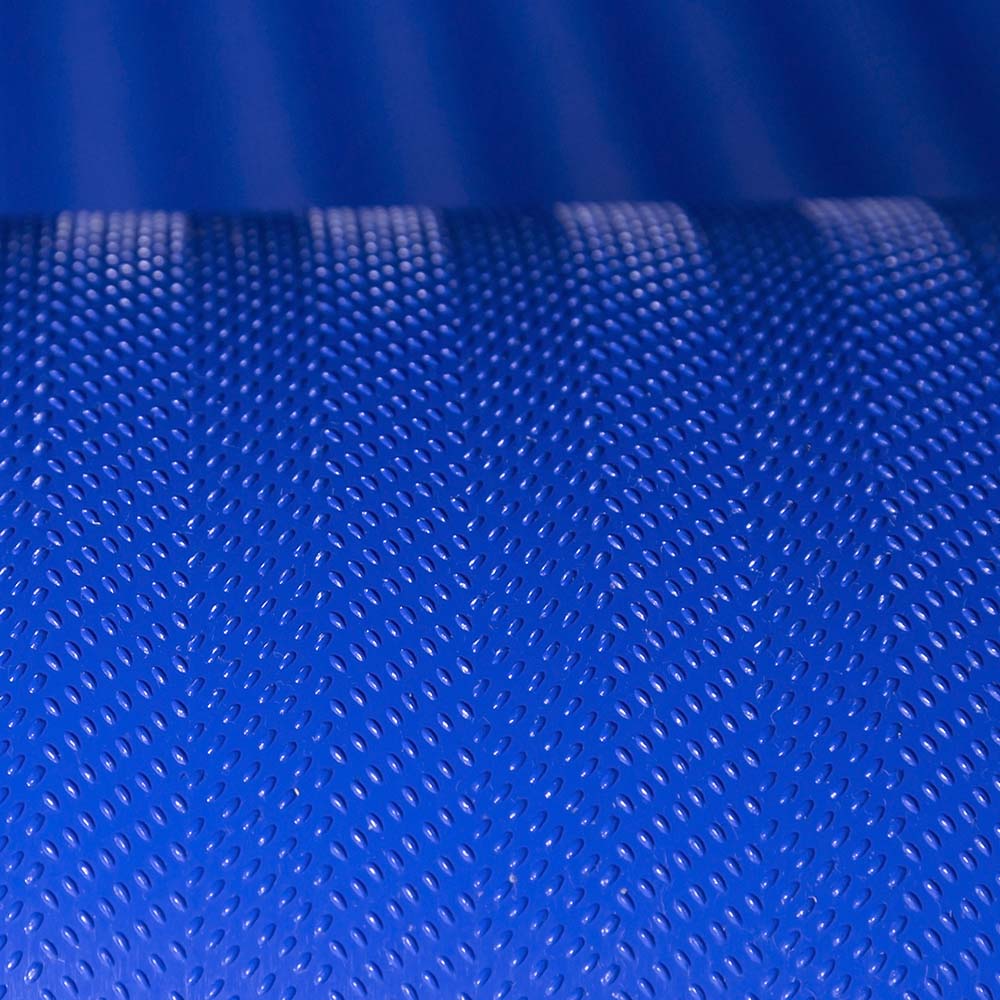

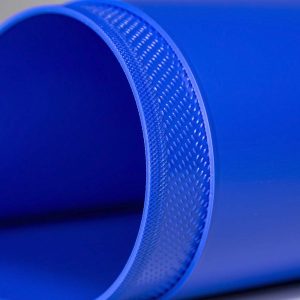

Two-ply blue belt with double TPU covers.

BELT FEATURES:

-

Silk matt finish on one cover.

-

Rice-grain A2 profile on the other cover, with rounded borders to prevent residue or grease accumulation.

-

Antimicrobial TPU with bacteriostatic formulation.

-

Low friction coefficient when wet.

-

High resistance to animal and vegetable oils and fats.

-

FDA and EU 10/2011 food quality.

-

Possible to weld cleats and sidewalls “Runer” on both covers.

-

Possible to seal edges of the belt.

BENEFITS:

-

Good release of products. Easy to clean.

-

Protection of bottom cover while being able to work on slider beds or rollers. When used as top cover, has good grip and easy release of products.

-

Prevents biofilm effects from forming. Long lasting antimicrobial effect.

-

Efficient transfer of conveyed products, avoid accumulations.

-

TPU covers remain in good condition even with constant contact with oils.

-

Ensures food hygiene and safety.

-

Applicable to inclined conveyor.

-

Fabric layer is completely protected from moisture.

Special Belts

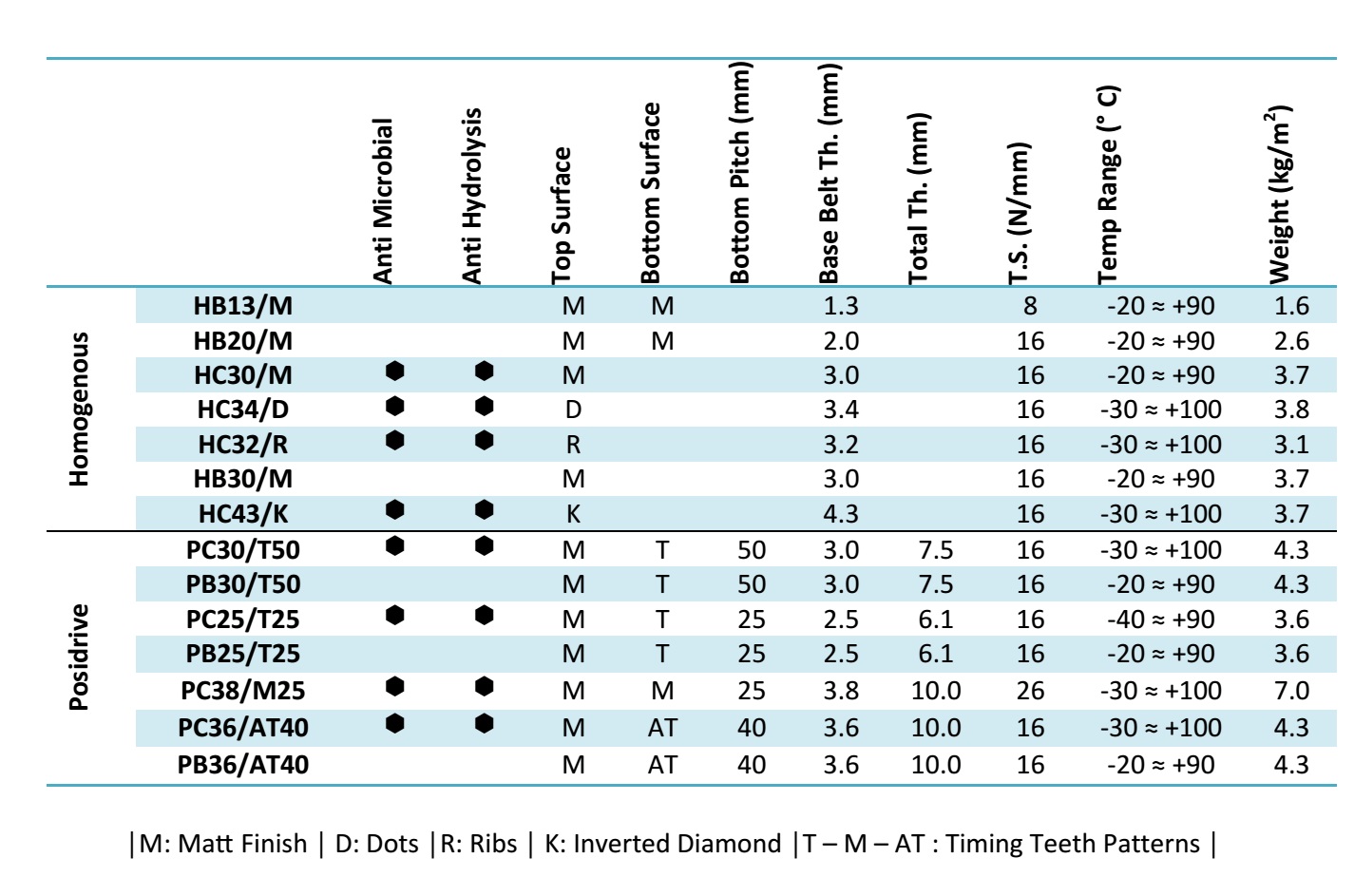

With the Autonomous self development of Microbes and Organisms to contaminate Biologically existing Foods like Meat, Poultry, Sea Foods, Milk based Products has called for an increase of the Stringency and Stipulations in Food Processing. Belts are the primary module to convey and the belts are the Primary mode of Contamination too.

The HPD Belts are developed with motive & provide the

- Increased Hygiene – Homogenous Layer of the TPU lets no Microbial Development and cleaning is easier

- Cost Savings – With low consumption of Water to Clean along with shorter maintenance cycles.

- Zero Elongation – With Kevlar Cords there is practically no elongation

An internal study was conducted which concluded 80% Lower Germ Development & Count & 50% Lower consumption of Water for Sanitation in comparison to the Modular Belts & Fabric Belts.

Physical Properties

- US & EU FDA Approved

- Toughable

- Oil & Fat Resistance

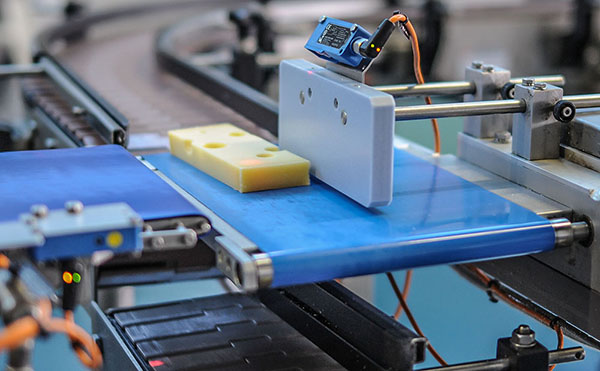

The Flat Belts for a Friction Drive – The belt is designed to be replaced onto the Conventional Conveyor System benefitting to Retrofitting, Easy Cleaning, No Fraying and Less Water Consumption.

The PosiDrive Belts – The belt is suited for a Higher Load and No Slippage Applications. The bottom surface of the belts are moulded with Timing Teeth, which enable uninterrupted operation.

Special Belts

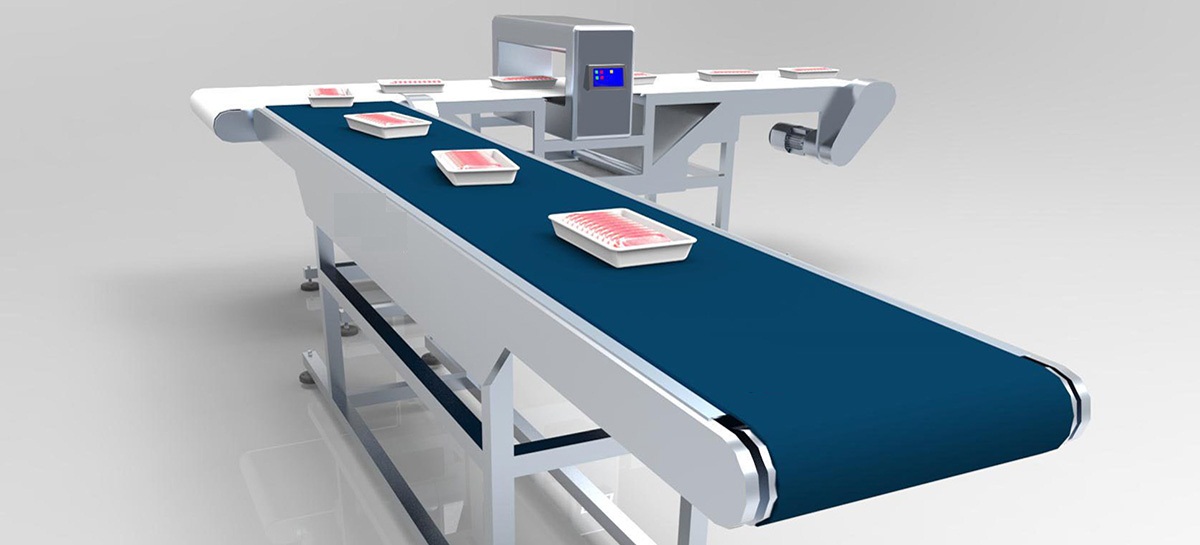

Enhance the level of protection of your customers and your brand reputation

For conveyors leading up to a standard metal detection control system.

Belt features:

-

Silk matt, homogenous, non-porous, easy to clean cover.

-

Excellent release of sticky products.

-

Wide range of temperature variance. Excellent thermal conductivity for cooling tunnels.

-

High abrasion resistance for abrasive products and scrapers.

-

Metal Detectable to enhance food stream inspection, protect brand reputation and demonstrate due diligence.

-

FDA and EU 10/2011 Food quality both the belt and their raw materials.

Paradise partners with DuPont to introduce a range of metal detectable conveyor belts which extends food manufacturers’ capabilities to detect food stuff mixed with conveyor belts through metal detection devices.

Our metal detectable conveyor belt maintains its high heat and chemical resistance, durability and flexibility. Even with its excellent wear resistant property, should the belt be accidentally chipped and mixed with the conveyed food stuff, it can be detected by standard metal detection system to avoid further food contamination.

Several tests have been carried out in food facilities and metal detectors to determine the detectability of our belts.

Now available in thermo-polyester blue (for belts and profile guides).

Special Belts

Enhance the level of protection of your customers and your brand reputation

For conveyors leading up to a standard metal detection control system.

Belt features:

-

Silk matt, homogenous, non-porous, easy to clean cover.

-

Excellent release of sticky products.

-

Wide range of temperature variance. Excellent thermal conductivity for cooling tunnels.

-

High abrasion resistance for abrasive products and scrapers.

-

Metal Detectable to enhance food stream inspection, protect brand reputation and demonstrate due diligence.

-

FDA and EU 10/2011 Food quality both the belt and their raw materials.

Paradise partners with DuPont to introduce a range of metal detectable conveyor belts which extends food manufacturers’ capabilities to detect food stuff mixed with conveyor belts through metal detection devices.

Our metal detectable conveyor belt maintains its high heat and chemical resistance, durability and flexibility. Even with its excellent wear resistant property, should the belt be accidentally chipped and mixed with the conveyed food stuff, it can be detected by standard metal detection system to avoid further food contamination.

Several tests have been carried out in food facilities and metal detectors to determine the detectability of our belts.

Now available in thermo-polyester blue (for belts and profile guides).

Special Belts

Conveyor Belts capable of Magnetic Sensing facilitating Pin Point Positioning along with Vacuum Holding.

This allows the product to maintain its positon.

Special Belts

The Special Purpose Manufactured Dual Color Belt which operates as 1 Piece finding its application into a specific sector Highlighting the Color Contrast Sensing along with Vacuum Holding.